Stone Tools Made By Early Man

Posted : admin On 17.01.2020Content revised 170910 File last modified: 180216 Basic Stone Tools A Beginner's Guide for College Students Related Pages:, This page is intended to serve as a quick introduction to several kinds of Paleolithic stone tools referred to by prehistoric archaeologists. This page is devoted to stone points and blades, usually associated with hunting activities. Other kinds of stone tools include various hammers and grinding basins, not described here.

(Picture sources for this page are numbered in captions visible by holding your mouse over each picture and are expanded at the foot of the page.) Skip Directly to:,. Overview Flakes and Cores Stone tools were made by taking a piece of stone and knocking off flakes, a process known as 'knapping.'

When the flakes were used, the tools produced are referred to as ' flake tools.' When the core itself was used, it is referred to as a ' core tool.' (Naturally, smaller flakes could be removed from larger ones, so not all flakes came off of cores. Or alternatively, big flakes should be thought of as the cores for little ones struck from them. Don't worry about it.) Both cores and flakes were used all through the stone age, but there was increasing emphasis on flake tools as time passed and techniques for controlled flaking improved.

Percussion and Pressure Earliest stone tools, and those in which the stone knapper had least control over how the stone would break, were made by percussion flaking, that is, whacking a stone with something —usually another stone, appropriately called a 'hammer stone.' Whacking with something slightly softer than stone —such as antler— allowed somewhat greater control in some cases. Even for the best percussion knappers, however, it was difficult to hit the target stone with perfect precision. Greater precision could be achieved by placing a piece of antler or other hard material precisely where you wanted pressure applied, and then whacking on that. This mediation allowed you to have precise targeting of force, and still have all the momentum of a falling hammer stone going into the movement.

This is called indirect percussion flaking. Still greater precision was achieved through pressure flaking (pressing against a stone until a flake pops off). Typically pressure flaking was used to remove very small chips (even extremely small ones), and was used, for example, to straighten and sharpen the edge of a blade.

When pressure flaking was done with such materials as wood, bone, or antler, it was possible for skilled stone knappers to achieve truly excellent control over just how a stone would flake. These methods were normally combined, using percussion flaking to produce roughly the shape desired, followed by pressure flaking to finish the job. Materials Tools varied depending upon the stone available and its characteristics. Not all stone is equal. Obviously sandstone is far too soft to take an edge. Marble is also too soft.

Stone Tools Made By Earman

Granite is inconsistent in its hardness and won't hold a sharp edge, and so on. For most of the world's foraging societies, the preferred stone for most tools was whatever would take the sharpest edge, typically chert, flint or, where available, obsidian, which can be worked much like broken glass. (For other stones, see the section on, below.) (, ) Although obsidian flakes are capable of breaking with a startlingly sharp edge —sharper than steel— they do not retain the edge as steel does, so stone tools in actual use require constant sharpening, just as stringed instruments require constant tuning and dogs need constant feeding. They were sharpened by knocking off additional tiny chips along the edge, taking care to do it in such a way as to keep the edge reasonably straight.

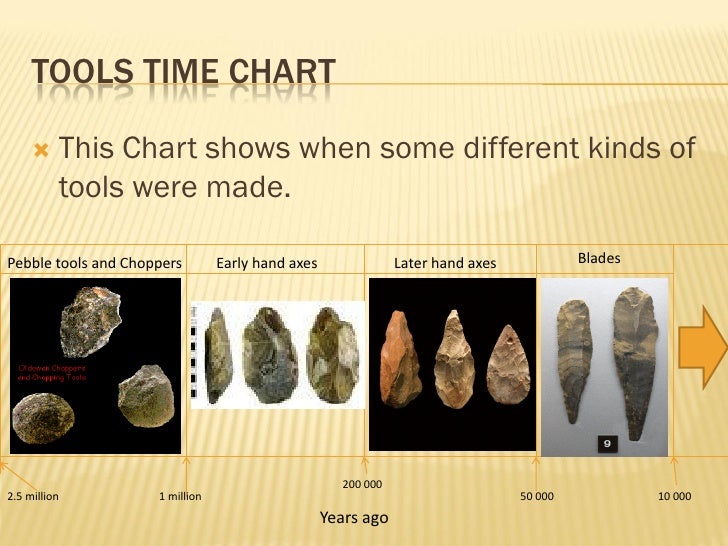

Naturally this technology became more refined over time. While earliest stone tools were little more than broken pebbles, the latest ones were sometimes miracles of controlled micro-chipping, culminating in the fantastically shaped 'eccentric flints' of some societies (notably Egypt and Mexico), which had lost all cutting function and were designed to show the stone knapper's skill and the owner's wealth. Choppers & Chopping Tools The term 'chopper' is applied to a stone, most often roughly spherical, from which several large flakes have been broken in order to produce a sharp edge or point. Choppers are typically crude and typically early. The Oldowan technology, for example, is characterized by choppers.

Most choppers use the natural breaks as cutting edges, but exhibit little retouching to lengthen the cutting edge beyond what is produced when a single flake is removed. The illustration at the right shows two views of the same chopper. In the upper view, a flake that has just been knocked off is laid beside the place from which it was struck. The lower view shows the pointed end of the chopper, as it would have looked from the perspective of the thing being chopped. Many specialists distinguish between 'choppers' often with only a flake or two removed to sharpen an edge, and 'chopping tools' which have flakes removed from two sides of the cutting edge. While choppers were made by Homo habilis, bifacial 'chopping tools' are found with Homo erectus, and merge into hand axes. The chopping tool shown at left is from northern China, but is almost certainly much later than Homo erectus.

Compared with the simple chopper above, notice how the skillful removal of a series of flakes has produced a nearly perfectly straight cutting edge. Hand-Axes Hand-axes are especially associated with the Acheulean tool tradition that followed Oldowan tools and was associated with Homo erectus life. A hand-ax is in many ways simply a refined chopper. It is flatter and may be chipped all the way around. Smaller, better controlled flakes are removed, so that the cutting edges can be longer.

Hand axes, like modern cleavers, had sufficient weight for heavy jobs, but good enough cutting edges for finer work, and were one of the most enduring tools in human history. The brown hand-ax shown in two views here is quite typical of Acheulean hand axes. The unchipped end would have been held in the hand, and the slight concavity on one side would have made an excellent finger grip. The other end was carefully retouched to provide a long sharp edge, although it was difficult to get a perfectly straight edge when it was produced by removing a series of small flakes. The hand-ax shown at the left is the effort of a modern stone knapper to produce an imitation of a later, Mousterian (Neanderthal) hand-ax.

He has tried to reproduce the greater attention to a straight edge, the greater number of small flakes removed, and the resultant greater utility of this implement. However notice that the 'handle' end has disappeared. A tool sharpened on all sides might have greater utility by providing a range of blade-shapes, but it would have required protection for the hand that wielded it. Some specialists speculate that a piece of leather might have been used to protect the hand while manipulating such an implement. (More About, ) Knives & Scrapers A hand ax obviously is a general purpose tool, used for hacking, scraping, poking, and other actions requiring a strudy tool with a sharp edge.

But more specialized tools are part of early tool kits, even if we do not always know quite what they were used for. They tend to be named for their assumed functions, their shape, or a combination of both.

Scrapers One of the special-purpose tools that emerges from earliest times is the scraper. One can think of this as designed to remove the yucky bits from the inside of animal skins, or the hair from the outside, but there are a great many scraping tasks involved also in vegetable preparation and in handling fibers for clothing —there is no reason to believe that all clothing was made of animal skins, after all. So we need to think of a scraper as a bit more all-purpose than the name at first implies.

For most tasks, scrapers needed to have long flat cutting edges, usually slightly curved. Nearly all are made from flakes rather than cores. Some are large and course, like the one shown above right, but many, especially in later times, were made of relatively small flakes, like the modern stone knapper's imitation shown at left, which is only about two inches long, and has been sharpened on one end for use in small tasks. Scrapers were specialized to various uses. Smoothing the sides of an arrow might require a notched scraper, for example, like the one at the right.

For many purposes one can imagine them being fitted with handles, like the modern reproduction shown below under 'hafting.' Scraping out a dish-shaped hollow might require a more defined curve, and so on. Not surprisingly museums are full of scrapers that appear to have been specialized in various ways, at least until they were grabbed for use for some other task.

Burins The action of scraping is closely similar to the action of scoring, and a specialized kind of scraper was the burin, which had a barb sticking out the side. The barb made it possible to cut a long slot in a piece of wood or antler (or anything else). One important Upper Paleolithic use for burins was to cut two long narrow slots in a piece of bone or ivory and then carefully break out the piece between the two slots for use as a needle, one of the critical inventions in the history of clothing.

Any slight bulge carelessly left on the side of a scraper can allow it to function as a burin, so the line between scrapers and burins is often difficult to draw. The 'burin' shown here, with the small barb on the lower-left side, was found out of context. It may or may not have been intended to be a burin (depending on whether the barb was deliberate). For that matter, it may or may not actually be prehistoric. The three 'scrapers' in the picture above all have small barbs which might justify calling them 'burins' for some prehistorians.

Awls & Projectile Points Punching holes in leather is a common enough challenge that many modern pocket knives include an awl, merely a pointed piece of metal, often out a sharpened blade on the side. Some Upper Paleolithic stone tools have roughly this shape and are usually identified as serving largely this purpose.

The prehistoric black one and the modern yellow one shown here are examples. However, the barb on some burins is quite large, and therefore burins and awls grade into each other.

The awls shown here might be classed as burins by some prehistorians. Far more complex are the points used in hunting, including arrowheads, spear points, and the like.

These have been found in a wide range of shapes and sizes —what was needed to kill a bird with an arrow was different from what was needed to kill a bison with a spear— and the points were made of a range of kinds of stone, depending on what was locally available. In general, a wee point —one the size of your fingernail— is an arrowhead, while anything larger than your thumbnail is heavy enough to be a nuisance on an arrow, and is probably a spear point. (Some arrows were simply pointed wood.

See below.) Since a skilled stone knapper can produce an arrowhead, say, quite quickly, but may take much longer to produce a straight, feathered arrow, it was usual among hunters to use a two-part arrow shaft. The front portion or 'foreshaft' had the point hafted to it.

It was then fitted to the main shaft. This arrangment facilitated retrieval of the labor-intensive main shafts even if a foreshaft was lost, as well as allowing a hunter to carry many specialized points with only a handful of arrows. The picture at the right shows a foreshaft attached to a main shaft. It has been bound for reinforcement where the two meet. Archaeologists have created typologies based on both form and function to help in reconstructing the history of human settlements in particular regions. A separate page on contains illustrations of some common projectile points found in North America. For present purposes, the examples given there can illustrate the genre.

Terms frequently used for specialized kinds of points associate them with thrusting spears (heavier points), with throwing spears (which must be lighter), with arrows (used with bows), with darts (used with atlatls and blowguns), with harpoons (with separable handles), and with leisters (with multiple prongs). Hafting a stone point to the shaft (or foreshaft) of the spear or arrow has traditionally been done by wedging it in and tying it down with animal sinews or plant fibers and/or through the use of bitumen. The picture at the right shows two different ways in which North American arrow heads were shaped with notches to facilitate hafting. Both arrows were intended for use in hunting deer.

An arrow's wooden shaft is usually thick enough that, even if it is carefully bevelled, it protrudes beside the blade enough to slow down the arrow as it enters the animal's hide. The arrow shown at left was made to sell to tourists; its clumsy hafting would be inefficient in real hunting. It is obvious that projectile points require hafting, that is, fastening to the end of a spear, arrow, dart, or whatever. (An arrow head without the arrow is not entirely useless, but it won't work as an arrowhead that way.) But hafting was not limited to spear and projectile points.

Except for earliest choppers and hand axes, most stone tools were likely fitted with handles. Scrapers and knives in various shapes might be left unsharpened or deliberately dulled on one edge to avoid cutting the user's hand. For some purposes this works well. However for other tasks or with other shapes, handles work better.

They are only rarely preserved, but it is pretty clear how they worked. The stone was mounted in a handle by tying or by using tar or resin. The picture at the left shows a Neolithic scraper forced into a handle made of a large bone. The modern copy of a very similar stone scraper on the right shows how it would have been forced into a wooden handle and then tightly tied in with rawhide (as was done by the Monongahila of southwestern Pennsylvania into the XIXth century). The beautifully made modern 'pizza knife' shown below, based on Upper Paleolithic French archaeological finds, illustrates how a blade would have been tied, using animal sinew or plant fiber, to a handle made of horn. Blades 'Blade' is arbitrarily defined by most archaeologists as a tool that is at least twice as long as it is wide, with sides roughly parallel. It would be reasonable to say that it is also a very thin tool.

Blade tools appear in the Upper Paleolithic. They were made by detaching the longest possible flake from a core, and then carefully retouching the edges of it as necessary to achieve exactly the shape and cutting edge needed. Blades required a considerable degree of skill to produce without breaking, since they were thin enough to be fragile. In use, blades were, so far as we know, usually hafted to wooden or antler handles, and by late Paleolithic times it was not unusual to use a series of quite small blades, lined up in a slot in a piece of wood or antler and glued in with naturally occurring tar (bitumen) or tree resin.

By the close of the Paleolithic such 'microflints' became typical tool parts. In Europe prehistoric archaeologists identify a stage they call the 'Mesolithic,' characterized by the dominance of microflints. A famous example is the Azilian archaeological tradition. Blades were critical for making deep holes, including deep wounds in prey animals, but they were also useful in other ways, and represented a huge improvement in the amount of cutting edge that could be gotten from a piece of superior stone.

(One estimate suggests that two pounds of stone provides about four inches of cutting edge as a handax, but up to 75 feet of cutting edge when turned into blades. That is an increase of about 225 times. It is important to remember that cutting edge length is not the only property that matters in tools, of course. If it were, our kitchens would have only long knives.) The blade tool seen above from both front and back in the illustration with the yellow background is quite typical for late Paleolithic times, and represents a considerable degree of skill in its production. The one with the red background is a modern imitation, made of high-grade obsidian. Notice the intensive 'retouching' that sharpens the edge by removing tiny chips of stone.

Stone Tools Made By Indians

Materials Other Than Stone It is important to remember that we have stone tools because they are easily preserved. In contrast, especially for very early periods, it is rare for archaeologists to find examples of tools made of materials easily lost. Such items range from flexible plant fibers used for clothing, basketry, fencing, or shelter thatch, to dense but ultimately impermanent materials like wood, ivory, antler, or bone. Many, probably most, tools used in the Paleolithic were surely NOT made of stone.

The modern Amazonian toothed knife shown at right above is made of bone, with the teeth carefully notched into it. The modern Costa Rican arrow points shown at the left are wooden. The modern Icelandic 'letter opener' below right is made from a sheep's horn with a wooden handle (with bark partially removed and partially retained).

The 'cutting' edges have not been sharpened but could have been. Similar tools made and used in the early Paleolithic would almost surely not survive to modern times. (We do in fact have some bone and wood tools from late Paleolithic times.) But even the earlier Lower Paleolithic surely had non-stone tools. It seems inconceivable that a form such as Homo habilis would have made the stone choppers that we find but would never have used a stick to pick his teeth, or that Homo erectus would have hunted with a stone-tipped thrusting spear, but would never have done anything with a pointed wooden pole. We know that wood and bamboo can produce remarkably sharp points and that they are still used as skewers today. Why should we imagine skewers to be a modern or even an Upper Paleolithic discovery? Curators at the Wangfujing Paleolithic Site Museum in Beijing wisely included a life-sized waxwork (above) showing a wooden spear being sharpened with a stone scraper as a reminder of this.

In fact, at that site (dated at 22,000 - 23,000 BC) a fair number of bone and wood tools were recovered, including the bone burin at the left below and the bone points (possibly awls) at the right. The picture at the left shows Ancestral Puebloan (Anasazi) awls made from turkey bones from New Mexico, probably dating from about AD 1100. The picture at the right shows a scraper made from an antelope leg bone, also Ancestral Puebloan. Although less durable, these bone artifacts are comparable in function to some of the stone ones shown higher up the page.

Five Free Decorative Funeral Programs from Hoover Web Design offers a set of that you can choose, download, edit, and print for your loved one’s memorial service. You can also add a, a favorite saying, or one of these. Download template zw jam minimalist. • Page 4: The final page of the program is the family’s opportunity to thank those who came to pay their respect. • Page 3: The third page provides the service order.

We must also remember that most tools, whether of stone or of other materials, could serve many purposes, and that broken tools could sometimes still have utility as something other than what was originally intended, just as modern people use old toothbrushes to clean all sorts of non-teeth. Furthermore, some tools identical in form may originally have been intended for different functions. For example The modern Huron bone awl shown at right has been tied by a length of rawhide to the knuckle bone of a deer to create a children's 'ball and cup' or bilboquet game, considered by the Huron to teach patience as children try to master the difficult task of tossing the knuckle into the air and catching it on the awl point. If it had been found in a Paleolithic context, with the leather long since rotted away, it is unlikely that it would have been interpreted as a game. The best guess would have been that the awl was an awl, and that the pierced knuckle bone was possibly a bead. Ground (Polished) Stone Chipping (knapping) is not the only way in which stone was processed in prehistoric times. Indeed, it was useful only with the most glass-like stones —flint, obsidian, and chert in particular— all of volcanic origin, where it was possible to knock or press off small flakes to leave a sharp edge.

But some tasks, such as cutting down trees, do not require a sharp edge so much as heavier, sturdier tools. The same rocks that have the sharpest edges when chipped, are too fragile for many heavy tasks. Slate, granite, schist, and limestone are difficult or even impossible to flake. Toolmakers using these materials had to start by laboriously pecking the rock into the desitred shape, then finish the tool by grinding and polishing. Most of these early ground stone tools were made for woodworking —items like axes, chisels, and adzes. (Christopher J. Ellis 2013 'Paleoindian and Archaic Hunter-Gatherers' IN Marit K.

Stone Tools Made By Early Man Information

Muston & Susan M. Jamieson (eds) Before Ontario; The Archaeology of a Province. Montreal: McGill-Queen's University Press.